At Warehouse Appliance, we have spent years educating homeowners and business owners on the benefits of gas refrigerators that operate on the principle of absorption refrigeration. This is a highly effective process that helps keep perishables, such as food and medicines, cooler. But what is an absorption fridge? Fortunately, it is exactly what the name implies and can be better explained as you read further. Learn more about the process of absorption refrigeration below:

What is an Absorption Refrigerator?

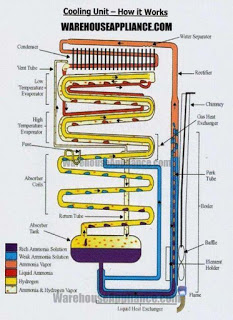

Simply put, absorption refrigeration “absorbs” the heat inside the fridge, absorbing the warm air from the interior and expelling it to the exterior. Removing the heat makes the air inside the fridge cold. Within the gas refrigeration industry, this process is accomplished by using a sealed absorption system containing a solution mixture of ammonia, water, sodium chromate, and hydrogen. The mixture is boiled by a flame usually fueled by either propane gas or natural gas, which are both common with absorption refrigerators.

The absorption unit or “Cooling Unit” is located in the back of the fridge in a sealed box, which contains an array of steel pipes. The gas is used to heat the absorption unit. The heat produced by the gas, which is located at the bottom of the unit, activates a chemical mixture inside the cooling unit. When hot, this mixture changes from a liquid into a vapor and begins moving to the top of the unit in the same way coffee is made in a percolator.

The active ingredient is ammonia, which turns from liquid to vapor and back to a pure liquid again. This pure ammonia liquid absorbs the warm air through aluminum plates on the fridge back wall, freezer back wall, and freezer floor. This system uses no motors, compressors, or any moving parts. This is all accomplished by heat boiling the solution and rising to the top of the sealed system where gravity takes over and allows the liquid to flow through the coil system at a rate determined by slight downward angles of the tubing.

Because it is at the top of the refrigerator, the liquid ammonia absorbs the heat in the freezer compartment first and continues flowing down to the fridge. If the ammonia has not reached its maximum absorption in the freezer, it will continue to absorb heat from the refrigerator as it moves down the pipes. This process is the reason the freezer cools down before the lower part of the refrigerator.

This system is very simple in operation but very complicated in design. A very slight change in angle can alter performance and lower efficiency. A couple of percentage differences in the solution ingredients will also change the gas refrigerator’s performance. Any weakness in a weld will shorten its lifespan. All these factors must be correct in order to produce an efficient absorption refrigeration unit with top performance. Strict quality control is vital for good production results.

Warehouse Appliance Recommends EZ Freeze for Gas Absorption Refrigerators

At Warehouse Appliance, we rely on our many years of experience in using gas absorption freezers and fridges, servicing gas refrigerators, repairing gas fridges, and our warranty records to make the business decision to promote the best brand. We choose the EZ Freeze brand.

We rate the EZ Freeze quality control as the best in the industry. EZ Freeze is the only company that produces the absorption system in-house at the factory. No outside contracting is used in production. Over 50% of the production process is centered around quality checks within the production line of the product. A high-pressure flushing occurs immediately after the welding process is complete to remove any weld slag or foreign objects that may be inside the coils.

The absorption system is then baked in an oven to relieve stress and reduce the risk of stress cracks during its lifespan. The oven baking process also aids in sterilization of the internals of the absorption unit prior to filling, baking off the oils and impurities. Each unit is then pressurized and leak-tested before installation in the cabinet. The EZ Freeze absorption units are all made on a jig and foamed in a mold and are interchangeable at any time in their life span with a new unit. This promotes consistency and reparability. It may seem excessive, but after all, this is the heart of the absorption refrigerator. It is also the most labor-intensive part of production, so it must be 100% before the unit ever gets to the consumer.

Further down the production line near completion, each unit is tested in the factory “Hot Room,” which simulates a harsh operating environment with temperatures of 100 degrees Fahrenheit and high humidity levels. Each unit must pass well within the limits of good food-keeping temperatures after this 16-hour torture test. The results are recorded on each refrigerator prior to packaging. No other company within this industry does this.

When asked about these strict quality control issues, EZ Freeze ownership replies, “We realize that most of our fridges are used in remote areas; which are inherently hard-to-get-to-and-from areas. It puts a great hardship on the consumer if there is a failure, and we just don’t want to see that happen.”

For more information on the history of propane refrigeration, explore our guide.

Contact Us Today to Learn More About Absorption Refrigeration

Warehouse Appliance is a top supplier of propane and natural gas refrigerators that utilize absorption refrigeration. This incredible process helps ensure goods can stay cooler, especially in remote locations. For more information on absorption refrigerators and our selection of options, contact our team today!